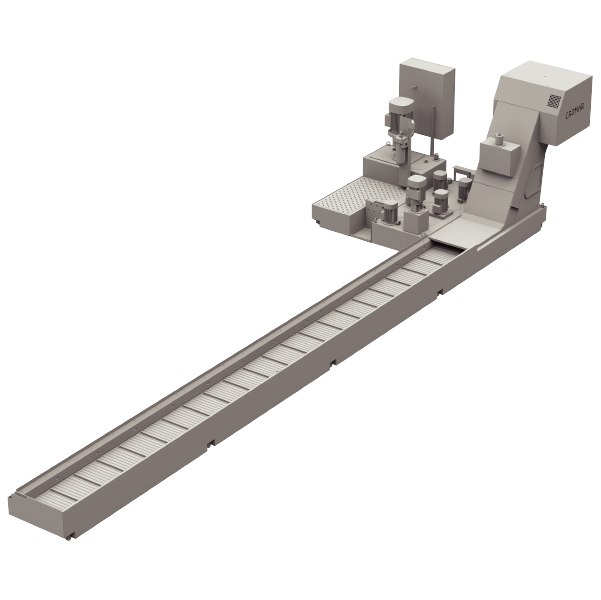

Series III

Series III conveyors are free standing integrated swarf /filtration management systems, designed to handle a variety of materials.

How it works

Series III filtration systems are essentially two conveyors backed up by self cleaning drum filtration. Designed for all types of swarf the upper slat hinge belt removes the bulk swarf from the machining envelope, this can be anything from turning stringy to chip. Fine particles are carried through the belt and sides to the lower scraper belt where the drum is located. Here the coolant has to pass through he 240micon mesh on the drum, with the chips being flushed off the drum on to the floor of the lower conveyor to be scraped out. Clean coolant passes to the clean tank

Optional Extras

- Additional coolant capacity/ tank size

- Additional pumps wash down, 20 bar coolant, spindle wash

- Super clean tank and HPC 70 Bar Coolant system

- Coolant Chiller

- Touch screen control system

- Wash gun

- Oil skimmer

- Mist extraction

- Installation

Controls

Are bespoke designed to the customer / machine interface requirement.

Controls

All conveyors are supplied finished to suit the customers colour specification. Our finish is Powdercoat.

Get in touch

Please fill out the form below and our team will be in touch