Tramp oil is one of the most significant causes of quality deterioration in cutting fluids, as well as a contributing factor in wear and tear in tools, loss of surface finish quality, and in particular reduced machine tolerances.

If the tramp oil is not constantly separated out the cutting fluid must be continuously replaced, which will involve significant long-term costs. The tramp oil also contributes to bacterial growth in the cutting fluid that are then spread by airborne fluid particles. This can result in allergic reactions and is also a source of foul odours in the workshop environment.

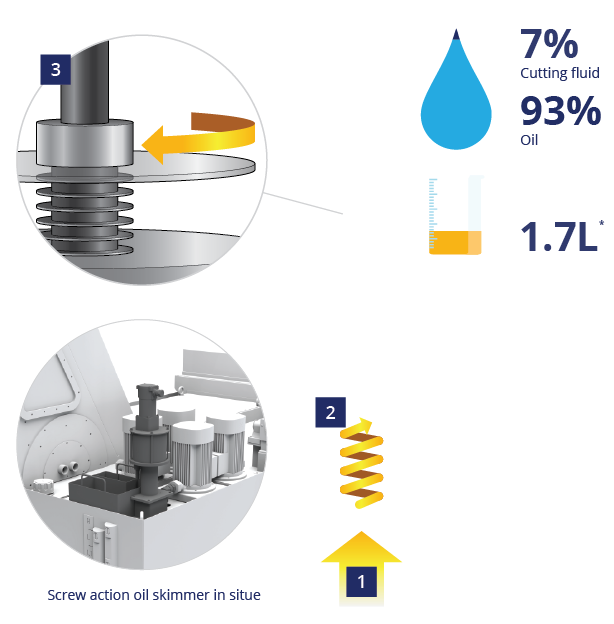

The Cromar screw action oil skimmer exploits the viscosity differential between oil and cutting fluid, with the more viscous oil clinging to the rotating threaded device (see point 3), from where it is separated out.

How it works

1. The tramp oil has a greater viscosity than the cutting fluid and will therefore stick to the thread.

2. The oil is then drawn up the rotating thread where it is separated.

3. The tramp oil is continuously scraped off by a rotating metal plate that is attached to the threaded column.

* Results from a performance test conducted at one of the largest automotive companies in the world during a test period of 6 hours.

Get in touch

Please fill out the form below and our team will be in touch