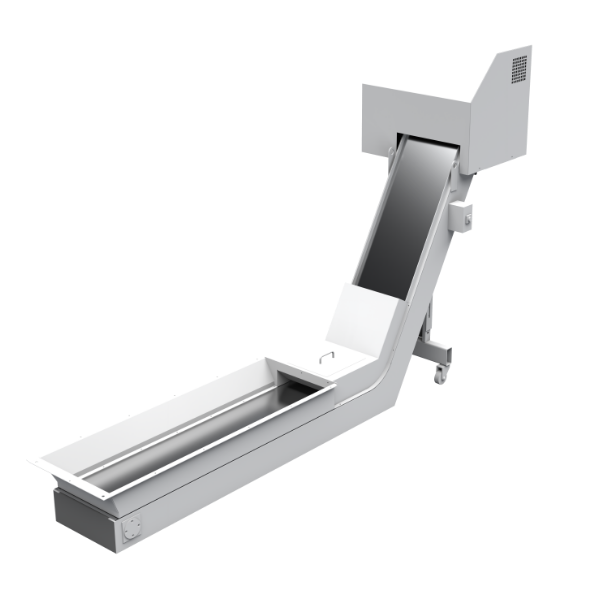

Magnetic Conveyor

Assists in the removal of Swarf from Machine Tools or Slugs / Punches from presses.

How it works

The conveyor incorporates sequential running magnets attached to a hollow bearing roller chain mounted below a stainless steel skin. The belt is driven by an externally mounted motor drive. Coolant on wet applications cannot penetrate below the Stainless steel skin, and the coolant discharges through a pinch point tunnel leaving the swarf attached to the stainless skin. Swarf then inches up the incline becoming dry, discharged off the neck of the conveyor upon demagnetization in to an optional swarf bin.

Magnets are manufactured from Strontium Ferrite Ceramic material magnetised to saturation remanence (3700). They are capable of the continuous handling of ferrous materials within general machining applications under normal operating conditions.

A range of productivity enhancements are available including integrated coolant tank, coolant pumps and machine control interface as well as any special requirements requested by the customer.

Features and Benefits

- Suitable for CNC lathes and machiningcentre applications

- Ideal for the management of small ferrousmaterials in general machining applications

- Enclosed case - No exposure to swarf/chips and coolant

- Minimal maintenance

- No wear

Principal Applications

- Vertical machining centre

- Horizontal machining centre

- Lathes

- Mill-turn/Multi-tasking machine

- Five axis machines

- Specialist machines

Suitable Swarf Types

Suitable for handling the following swarf types:

Small Chipped Swarf

Get in touch

Please fill out the form below and our team will be in touch