How it works

Provides a clear view of the production processes under toughest milling conditions. The spinning window is an approved system to keep inspection window clean and thus to ensure continuous control of workflow. Rotoclear is suitable for all kinds of metal cutting machines such as turning centres, milling machines, including machining centres and test stands.

“A rotating disc flings off striking coolants and cuttings, whether

water-soluble or water-insoluble.”

The main principle

A rotating disc flings off striking coolants and cuttings, whether water-soluble or water-insoluble. This enables the operator to always have a clear view into the processing area – safety according to safety instructions currently effective being guaranteed. Integrated air bleed keeps the system sealed and always operational. The self-governed control systems of the direct drive motor supports initial operation and standard operation without the need for adjustments on the Rotoclear. Overload safeties, emergency shut-off and soft restart are executed automatically and ensure constant operation.

Installation

The device is generally attached to the inside of the machine tool door at eye level. The inspection window is fixed by means of a screw hole circle, or, an adhesive flange is attached and fixed with the cover without perforation for the machine tool window. A two-component adhesive guarantees safe fixing. The bolt on or gluing process can be carried out by untrained staff with maximum process reliability by means of specifically developed mounting procedure. The installation can optionally be performed in original equipment manufacturing machines (OEM), or as a retrofit on processing equipment. For milling machines we recommend using the bolt-on flange version (polycarbonate glass) whereas the adhesive version is appropriate for turning centre.

Features and benefits

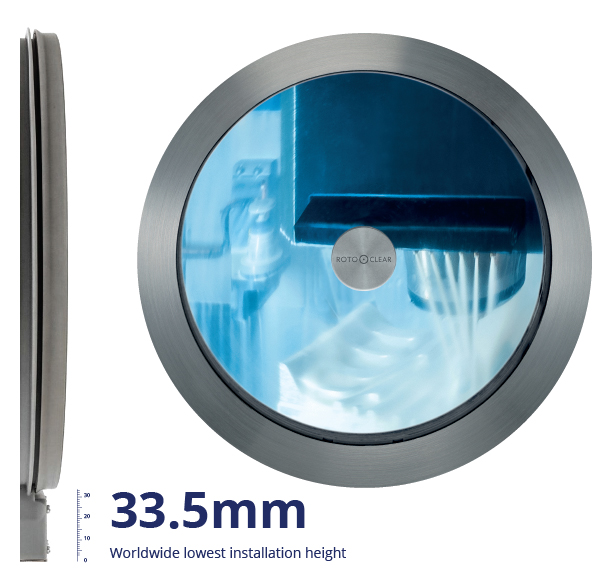

- Worldwide lowest installation height (33.5mm)

- Maximum field of view based on revolutionary and patented drive concept

- Unobtrusive design: from follows function

- Dramatically reduced service and cleaning times: the rotating glass disc as a wear part can be changed in less than a minute without dismantling the entire device

- Simple device installation either as the bolt-on or adhesive-mounted version

- Maximum operational reliability by use of air bleed

- Low power consumption by use of linear drive technology

- High torque for the toughest conditions (laminated safety glass VSG).

Get in touch

Please fill out the form below and our team will be in touch