Briquetting Machines

Sludecompact

Briquetting machine for the compaction of grinding sludge

Briquetting machine for the compaction of grinding sludge. The conveyor incorporates sequential running magnets attached to a hollow bearing roller chain mounted below a stainless steel skin. The belt is driven by an externally mounted motor drive. Coolant on wet applications cannot penetrate below the Stainless steel skin, and the coolant discharges through a pinch point tunnel leaving the swarf attached to the stainless skin. Swarf then inches up the incline becoming dry, discharged off the neck of the conveyor upon demagnetization into an optional swarf bin. Magnets are manufactured from Strontium Ferrite Ceramic material magnetised to saturation remanence (3700).

Supercompact

Briquetting press suited to be placed directly under the chip conveyor

EVTM-55-L is a compact briquetting machine which encloses all components into a single chassis. It is specially designed to be placed nearby the tool machine, and positioned under the chip conveyor belt. EVTM-55-L is provided with devices which allow it to operate in fully automatic mode. Moreover, the wheels and the handle, that make it unique, allow easy movements inside the workshop according to the production needs.

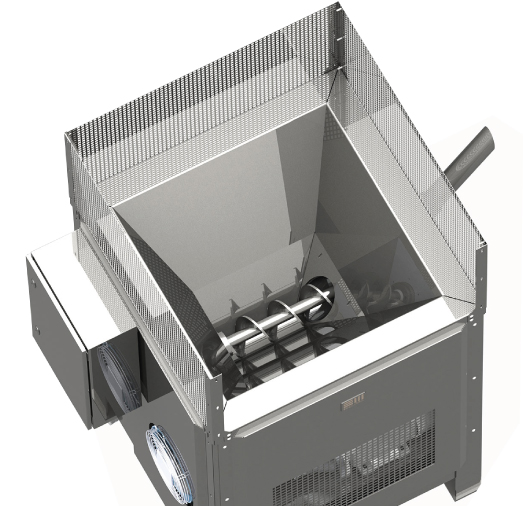

Smartcompact

High performance briquetting press fpr metal anc polymer chips

From Eidos Works innovation comes the new EVTM-65-L, a briquetting system of high performance in the most compact structure of the market. With a high capacity hopper and a feeding screw able to process various types of materials, it reaches important production levels. Fully automatic, it is able to recover most of the residual refrigerating oils and greatly reduce the chip overall volume.

Features and Benefits

- Up to 85% reduction of the overall volume of the scrap.Ideal for the management of small ferrous materials in general machining applications

- Increase of the economic value of the scrap.

- Reduction of time in managing the scrap.

- Recovery of cutting oils and coolants from the scrap.

- Reduction of the environmental impact.

Get in touch

Please fill out the form below and our team will be in touch