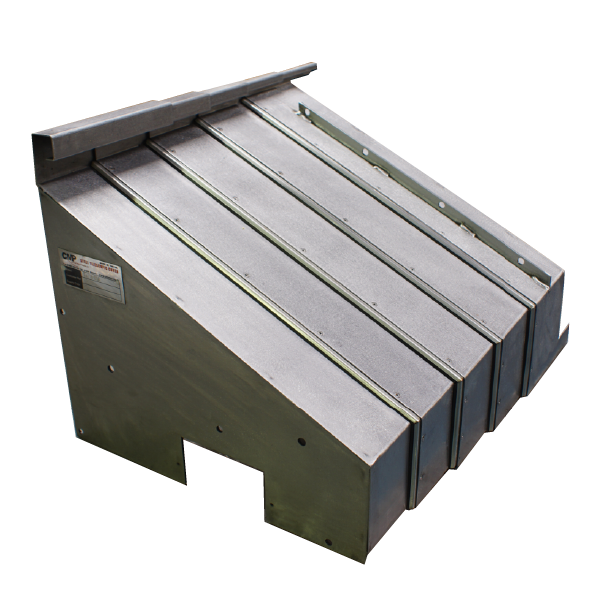

Air Blower/Comb Assembly

These 2 separate items are options on all types of conveyors.

How it works

They are primarily designed to remove swarf from the discharge of the conveyor preventing it from being carried back do in to the load length of the conveyor.

Air Blower

The air blower assembly consists of a regulator air valve and solenoid delivering air to a air pipe located in the head of the conveyor hood. Situated at such and angle this air knife blows swarf sticking to the conveyor belt off as it returns from the discharge position down the incline. Air knives are most effective on small chipped swarf, where the lubricity of the soluble or neat oil cutting fluid holds the swarf to the belt. The solenoid only opens to release air when the conveyor is indexing. The air valve also has a regulator on to enable adjustment of the amount of air released.

Comb Assembly

The comb assembly is again an optional product offered to help strip stingy swaf off the belt as it returns down the incline as part of its rotational cycle. Stringy swarf will often get jammed in the belt, side wings etc and will be dragged back down the incline. This can then cause issues getting jammed in the nose of the conveyor. To minimalize the occasion of this happening the comb assemble is positioned on the return of the belt to strip off any stringy swarf. Most recommend this product on heavy turning applications both Horizontal and Vertical turning where stringy swarf is common.

Get in touch

Please fill out the form below and our team will be in touch