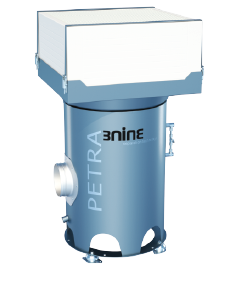

3 Nine Blue Line

The 3nine - Blue Line provides a healthier and safer working environment, allowing you to focus on your production.

How it works

The unique patented technology separates the oil mist and other coolants up to 99.9%* with a particle size down to 1μm by using centrifugal forces. This process requires a minimum of maintenance. A rotating disc stack separates the oil mist more effectively than traditional centrifugal separation technologies like cyclones and rotating filters. The rotor also functions as a fan evacuating the mist making external fans unnecessary.

The BLUE LINE series of units separate 99.9% of all fluid particles down to 1μm, 91% down to 0.9μm and 82% down to 0.75μm. In order to capture the finer particles that are <1μm, 3nine uses a HEPA filter (H13) to ultimately clean the air to 99.97%. With most of the particles separated in the disc stack, only 1% of the particles are collected in the HEPA filter.

Advantages

- Life Cycle Cost - Low

- 99.97% Particle free Air!

- Minimal Maintenance

- Minimal Filter Change

- Suitable for applications with high degree of solid particles

- Minimal Duct Work

- Recycling of cutting fluids

- No Oily Surfaces in the Workshop

- Compact and Direct Installation

- Low energy use

Suitable for use on machines with:

- Grinding Coolant emulsion

- Turning Coolant emulsion

- Milling Coolant emulsion

Suitable for use on machines with:

- EDM machines

- Sliding head machine using neat oil

- High pressure coolant applications 70 bar